Description

Custom Pillow Boxes: Functional and Appealing Packaging Solutions by Boxesly

In today's competitive marketplace, packaging serves two key purposes: protecting the product and projecting the brand's identity. For businesses seeking a distinctive and appealing packaging solution, Custom Pillow Boxes offer a unique combination of aesthetic appeal and practical functionality. Their characteristic curved shape stands out on shelves and provides a notable unboxing sequence for customers. Boxesly provides high-quality custom pillow boxes designed for the specific needs of diverse businesses, ensuring your products are presented professionally and attractively.

Understanding Pillow Boxes: Form and Function

Pillow boxes, named for their resemblance to a small pillow when assembled, are a popular packaging choice known for their curved shape and simple, secure closure. Typically shipped flat to save on storage space and shipping costs, these boxes are easily assembled by folding along pre-scored lines. The ends gently curve inwards and tuck into place, creating a secure enclosure without the need for tape or adhesive, although seals or ribbons can be added for extra security or decoration. This inherent design makes them an efficient and attractive option for a wide range of lightweight products.

Materials and Construction: Ensuring Quality and Appeal

The effectiveness of a pillow box depends significantly on the material used for its construction. Boxesly utilizes quality paperboard and cardstock, offering varying thicknesses (measured in points or GSM) to suit different product weights and desired levels of rigidity. Common material choices include:

- SBS (Solid Bleached Sulfate): Known for its smooth, white surface, SBS is suitable for high-quality printing, rendering vibrant colors and sharp details. It provides a clean, high-quality look appropriate for cosmetics, pharmaceuticals, and gift items.

- Kraft Paperboard: Offering a natural, rustic appearance, Kraft paperboard is often chosen for its eco-friendly association. Available in traditional brown or bleached white, it provides good strength and is popular for organic products, handmade goods, and brands emphasizing sustainability.

- Recycled Cardstock: For businesses prioritizing environmental responsibility, recycled cardstock options are available, offering a sustainable choice without significantly compromising quality or printability.

The construction process involves precise die-cutting and scoring to ensure consistent shape and straightforward assembly. The quality of these processes is crucial for the final appearance and structure of the pillow box.

Variations to Suit Specific Needs

While the fundamental pillow shape remains consistent, variations can be incorporated for improved function or appearance.

- Standard Pillow Boxes are the classic, adaptable design suitable for numerous applications.

- Pillow Boxes with Handles incorporate a die-cut handle (often reinforced) for convenience in carrying, making them useful for retail settings or gift packaging. Handles can be simple cut-outs or attached cords/ribbons.

- Pillow Boxes with Windows feature a strategically placed window patch (typically clear PVC or PET film) allowing customers to view the product inside without opening the package. This is particularly effective for showing items like confectionery, small toys, or jewelry.

- Size Variability means pillow boxes are not one-size-fits-all. Boxesly can produce them in a wide array of custom dimensions, from small boxes appropriate for jewelry or USB drives to larger formats suitable for scarves, ties, or apparel accessories.

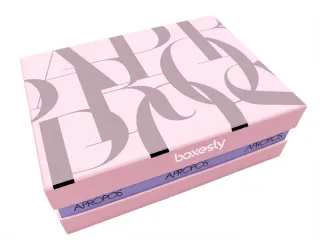

Customization: Branding and Appearance

Customization is how a standard pillow box becomes an effective branding tool. Boxesly offers a comprehensive range of customization options to ensure your packaging aligns with your brand identity and marketing objectives.

- Printing uses advanced technologies to achieve desired visual results:

- Offset Printing is suitable for large volume orders, offering good color accuracy (CMYK and Pantone Matching System - PMS) and crisp image quality.

- Digital Printing is appropriate for shorter runs, variable data printing, and quick turnarounds, providing good quality and flexibility.

- Inside & Outside Printing provides additional branding opportunities by printing designs, messages, or patterns on both the exterior and interior surfaces of the box.

- Finishing Options improve the tactile feel and look of your pillow boxes:

- Lamination (Matte/Gloss) adds a protective layer against moisture and scuffs while providing either a subdued, non-reflective matte look or a vibrant, shiny gloss appearance.

- Spot UV applies a high-gloss UV coating to specific areas (like logos or text), creating noticeable contrast with a matte background.

- Foiling (Hot Stamping) adds metallic accents (gold, silver, copper, holographic, custom colors) for a high-end and noticeable effect.

- Embossing/Debossing creates raised (embossed) or recessed (debossed) designs, adding texture and a subtle, refined dimension to logos or patterns.

- Structural Customization means requests for different window shapes, custom inserts (less common for pillows but possible), or specific closure mechanisms can be accommodated if required.

Benefits of Using Custom Pillow Boxes

Choosing custom pillow boxes from Boxesly offers numerous advantages for businesses:

- Improved Brand Perception: The distinctive shape and potential for high-quality customization create a quality feel, improving brand image and perceived product value.

- Better Customer Experience: The appealing presentation contributes to a positive unboxing sequence, supporting customer loyalty and positive associations with the brand.

- Adaptability: Suitable for a diverse range of lightweight products across industries – retail, gifting, cosmetics, confectionery, apparel accessories, event favors, and promotional items.

- Cost-Effectiveness: Pillow boxes are generally economical to produce. Shipping flat minimizes warehousing and transportation costs.

- Ease of Assembly: Their simple fold-and-tuck design saves time and labor in packaging processes.

- Adequate Protection: While not intended for heavy or extremely fragile items, they provide sufficient protection for jewelry, small garments, soaps, cosmetics, and similar goods.

- Effective Marketing Surface: Offers ample printable area for branding, product information, and marketing messages.

- Eco-Friendly Potential: Availability of Kraft and recycled materials appeals to environmentally conscious consumers and aligns with corporate sustainability goals.

Selecting the Right Custom Pillow Box

Selecting the appropriate pillow box involves considering several factors:

- Product Characteristics: Assess the size, weight, and nature of your product. Ensure the box dimensions are suitable and the material weight provides adequate support.

- Branding Objectives: Define the desired look and feel – high-end, eco-friendly, playful, minimalist? Your choice of material, printing, and finishing should align with this.

- Budgetary Constraints: Different materials, printing techniques, and finishes vary in cost. Boxesly can help you find options that meet your aesthetic goals within your budget.

- Usage Context: Consider where the box will be seen – on a retail shelf, handed out at an event, shipped directly? This influences design choices like window inclusion or handle necessity.

Boxesly’s team is available for consultation, offering knowledgeable guidance to navigate these choices and develop a suitable custom pillow box solution.

Why Choose Boxesly?

Boxesly is a reliable supplier for your custom pillow box needs. We provide:

- Quality Assurance through premium materials and meticulous manufacturing processes.

- Extensive Customization with a wide array of printing and finishing options.

- Knowledgeable Guidance through the design and ordering process.

- Competitive Pricing offering value.

- Timely Delivery so your packaging arrives as scheduled.

Conclusion: Improve Your Packaging with Custom Pillow Boxes

Custom pillow boxes offer a refined, practical, and cost-effective packaging solution that improves brand visibility and customer satisfaction. Their unique shape, coupled with extensive customization possibilities available through

Boxesly, allows businesses to create packaging that represents their brand and protects their products effectively.

Contact Boxesly today to discuss your custom pillow box requirements, request a quote, or explore design possibilities. We can help you create packaging that effectively represents your brand.